Single screw granulator uses special screw design, screw, barrel after special hardening treatment, with wear resistance, good mixing performance, which is widely used in the plastic industry, so what is the working principle of single screw plastic granulator?

The working principle of the plastic granulator is to send the classified waste plastics to the crushing and cleaning machine, crush them into flakes or strips, and then send them to the extruder. After melting and plasticizing extrusion at appropriate temperature, the impurities in the waste plastics will be further filtered out and extruded into strips (filaments). The air-cooled dryer will quickly blow dry the moisture attached to the extruded filaments during cooling, and then the traction granulator will cut them The cooled plastic strip is cut into particles with uniform size by the cutter, so the waste plastic becomes high-quality molding particles with uniform size and smooth appearance.

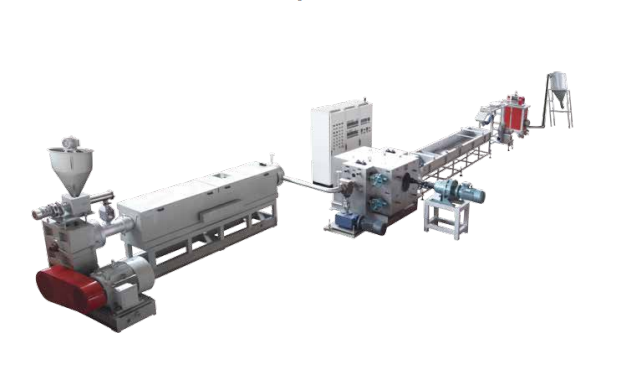

Single screw granulator

The above is the working principle of single screw granulator. The extrusion system of single screw plastic granulator is mainly an extruder. The extruder includes a chassis and a power assembly in the chassis. There is an electric control box outside the chassis, a reducer and a hopper on the chassis, and a barrel under the hopper There is a heating ring outside. Changzhou Dayun Environmental Protection Technology Co., Ltd. is engaged in single, twin-screw plastic granulator home, set design and development, manufacturing and sales services in one.

TEL:0519-87070068

Fax:0519-87071688

E-mail:sales@jwell.cn

Complaint:info@jwell.cn

Add: No.118,shangshang Road,Licheng Town,Liyang,Changzhou city,China

Official Account